Guo Mindong

+86 181 2433 8518

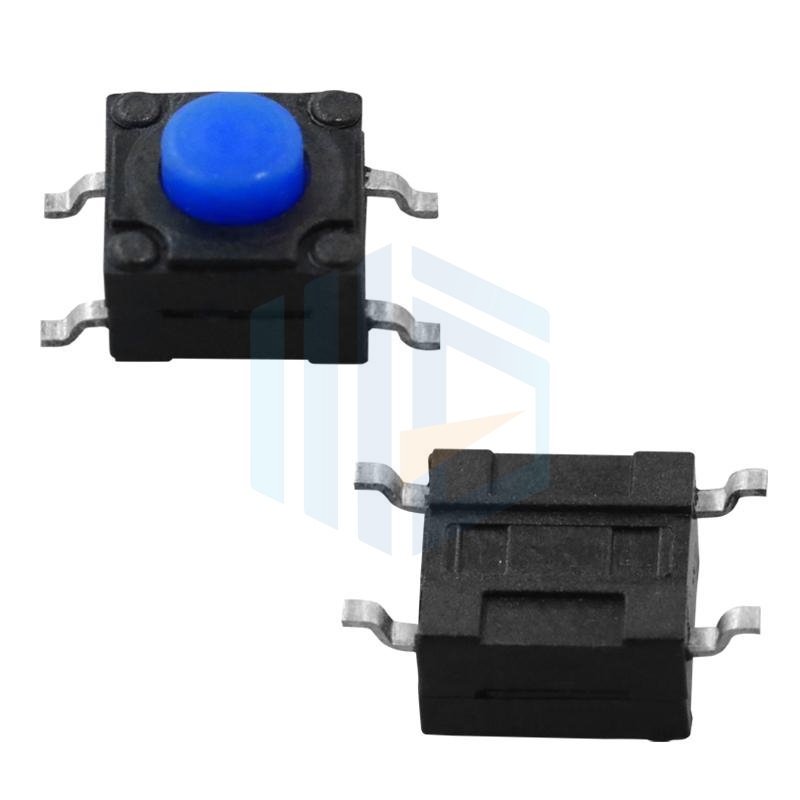

The demand for waterproof tactile switches is increasing in modern electronic devices, especially in devices used in humid environments such as outdoors, kitchens, and bathrooms. Making waterproof tactile switches requires a series of precise steps and techniques, which will be explained in detail below.

Step 1: Material Preparation

Firstly, collect the materials required for making the tactile switch. These materials may include waterproof casings, conductive materials (such as copper and silver), insulating materials (such as silicone), switch mechanisms, wires, etc. Ensure that the selected materials meet waterproof requirements and can work reliably in humid environments.

Step 2: Design the switch structure

Design the structure of the switch according to the requirements of the equipment and the usage environment. Consider factors such as the size, shape, and triggering method of the switch, and ensure that the design has waterproof functionality. Usually, waterproof tactile switches are designed with sealed housings, waterproof sealing rings, etc. to prevent moisture from seeping into the interior of the switch.

Step 3: Manufacturing switch components

According to the design, manufacture the various components of the switch. This may involve processes such as processing metal conductive components, injection molding or 3D printing shells, and making insulation gaskets. In the manufacturing process, it is necessary to ensure the accuracy and quality of each component to ensure the performance and reliability of the switch.

Step 4: Assemble the switch

Assemble the manufactured components into a complete switch. This includes installing conductive components, sealing rings, casings, etc. During the assembly process, special attention should be paid to waterproof sealing to ensure that the interior of the switch is not affected by humid environments.

Step 5: Testing and Debugging

After assembly, test and debug the switch. Testing includes power on testing, waterproof performance testing, etc. Through testing, ensure that the switch can work properly and has good waterproof performance.

Tip 1: Choose the appropriate materials

Choosing the appropriate materials is crucial when making waterproof tactile switches. For example, selecting water-resistant and corrosion-resistant metals as conductive components, and choosing shell materials with good sealing performance.

Tip 2: Precision machining

The production of waterproof tactile switches involves many precision machining processes, such as metal processing, injection molding, etc. To ensure the accuracy of the size and shape of each component, in order to guarantee the performance and reliability of the switch.

Tip 3: Strict Quality Control

Strict quality control is crucial in the production of waterproof tactile switches. Ensure that each step meets the requirements and conduct comprehensive testing and inspection of the finished product to ensure the quality of the switch.

In short, making waterproof tactile switches requires a series of precise steps and techniques. Through reasonable design, precise processing, and strict quality control, waterproof tactile switches with excellent performance, reliability, and durability can be produced to meet the needs of different equipment.